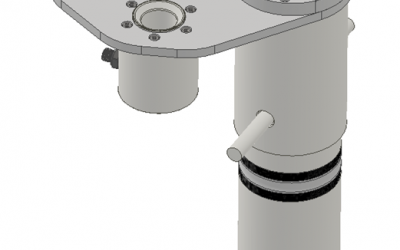

IK designed and delivered 4 off double barrier plugs to seal off 2” flushing lines / ports for the 12” production flowlines.

The client found the two 2” isolation valves between the receptacle and the 12” line to not seal 100% at low pressure. Hence, the client required double barrier plugs to be installed in the receptacle to secure the required isolation after the flushing operation was completed.

IK performed an initial study to explore several options for the sealing, the receptacle plug was settled for to be the best option.

The plugs were to be installed before the first oil to be recovered and the design and the manufacturing was performed at over a period of 3 weeks. This was made possible by applying the CBER-method, Competency Based Emergency Repair. This is a project execution method developed and used by IK for several urgent deliveries over the last 15 years. The plugs were then sent offshore and successfully installed onto the subsea receptacles according to agreed contract and the client could start up the field as planned.